There are many types of concrete blocks used in construction that can be specified for every situation, from the top of the concrete foundation to the apex of a gable end. Blocks are versatile, can be lightweight, and even have thermal retention properties.

Concrete blocks are able to be used in many applications and can significantly speed up a masonry build. Use them to build internal partitions, external garden walls, or as part of a beam and block flooring system.

What are The Most Common Concrete Blocks?

Concrete blocks come in a wide range of specifications, designed to be used in a number of locations. With a lot of choice available it can sometimes be difficult to be certain which block is right for your project.

The three main categories of concrete block are based on density, which denotes strength. The denser the block, the more weight it is able to carry, but biggest isn’t always best.

Lightweight Concrete Blocks

The most commonly used concrete block for domestic extension projects, and other light builds is the 3.6N aerated block.

- Lightweight concrete blocks can be supplied either solid, or hollow

- Hollow blocks can be handled easily, and the open interior can take either concrete reinforcement or foam insulation

- Solid blocks can be cut to fit while retaining insulating properties

Medium Density Concrete Blocks

The medium dense block is a good multipurpose product, and this type of concrete block is usually available in both 3.6N and 7.3N strength.

- Medium density blocks are versatile, strong and can be used in most applications

- Fire, sound and moisture resistant, use them everywhere on a build

Solid Dense Concrete Blocks

Solid dense blocks are most often used in below ground locations or where additional loadbearing performance is required from 7.3N to 10N, and more.

- Solid dense concrete blocks are the heavyweights of the concrete block range

- Great for external works, foundations and high loadbearing situations

Coursing Blocks

Coursing blocks are recommended for regularising levels, or openings around doors and windows. However, they should not be used in place of padstones that may be required to support lintels.

- Coursing blocks save time cutting and help maintain a consistent level and finish

- Coursing blocks share the properties of standard blocks and should be used in conjunction to maintain consistency of structural integrity

Concrete Blocks Commonly Used in Construction in the UK

Lets get into a deeper dive into what types of concrete block are available, and what the differences between them mean.

What is a 3.6N Lightweight Concrete Block?

The letter N designates the strength of a concrete block, and 3.6N is the lowest grade. The numbers tell us that it is able to support over three-and-a-half tonnes of direct force. As such it means that a 3.6N concrete block is ideal for many applications.

Use 3.6N blocks for:

- Beam and block flooring

- Internal partition walls

- Inner leaf of a cavity wall

- The upper floor of a two-storey build

Can I Use a 3.6N Block on my Foundations?

Yes, is the short answer. They can be used to build a wall from the foundations up to the top of a single storey extension, or garage.

A Thermalite Shield Aerated Block also has excellent thermal retention properties that can contribute to the overall Part L compliance required for UK building regulations.

What Does Aerated Concrete Mean?

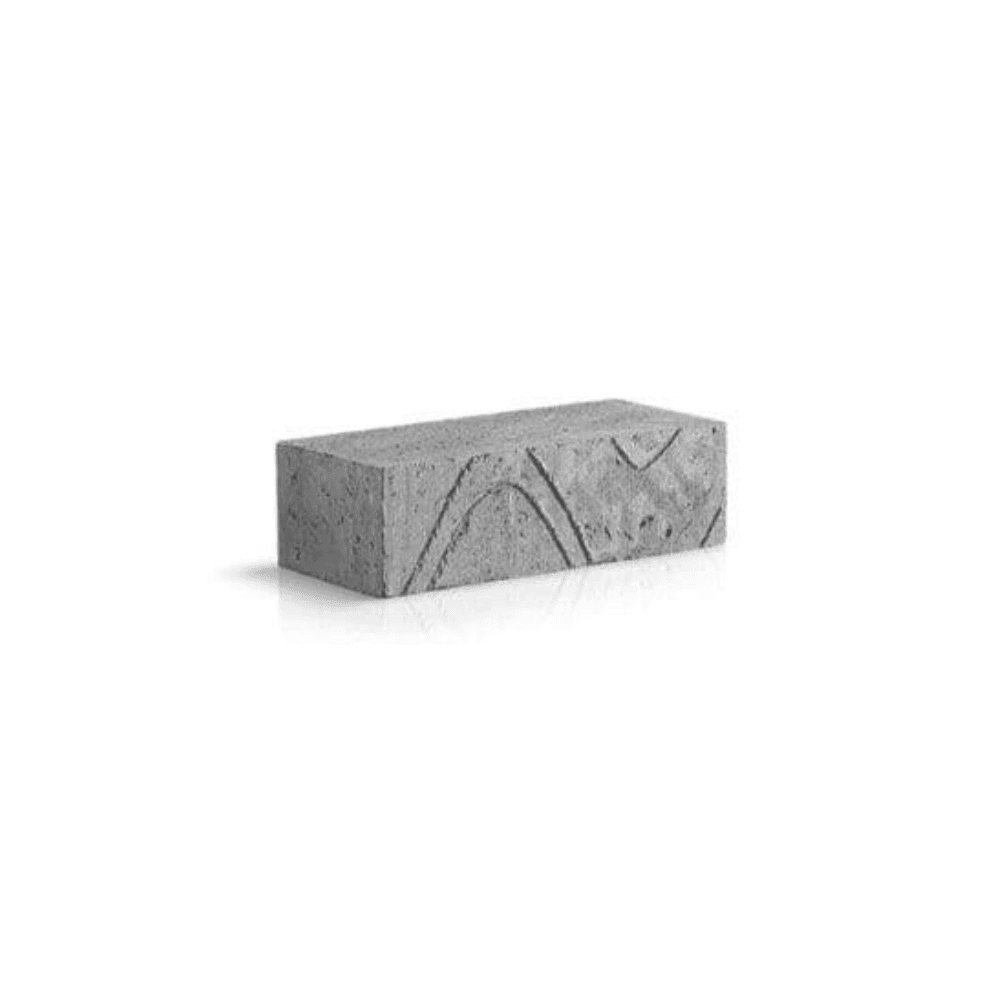

Aerated blocks are made using aluminium powder and hydrogen to produce a foam that results in resilient concrete blocks that are approximately half the density of regular concrete. The blocks are filled with millions of tiny air bubbles up to about 3mm in diameter.

It is these aerations that deliver the block’s thermal insulation properties.

Are Aerated Concrete Blocks Any Good?

If you are looking for a lightweight block that is easy to handle, then an aerated Toplite Concrete Block will fit the bill. These blocks are 100mm by 215mm by 440mm and can be picked up in one hand.

An aerated block is easy to cut using a standard large tooth hardpoint saw, blocking chisel, or bolster. This makes them a firm favourite for awkward coursing situations where you need to get creative!

Best Practice:

Make sure your lightweight aerated blocks are stacked safely on a pallet above well drained ground and are properly covered if left outdoors for any length of time as they may absorb water.

What Is A Medium Dense Block?

Medium dense blocks are great if you need a Robust Detail to inhibit sound transmission and they are ideal as a part of a build’s fire resistance strategy. If used on an external elevation either render or clad the wall with a proprietary rainscreen material.

Use Medium Dense Blocks for:

- External applications, such as rendered outer leaf walls

- As part of a robust detail for sound deadening

- As part of a party wall detail for fire risk management

- Gable ends and structural columns

Qualities of Medium Dense Concrete Blocks

Medium density concrete blocks are 100% non-combustible and will make no contribution to any fire event. If you require a block that is A1 fire rated, a medium dense block will fulfil the brief.

When painted, and mortared correctly, they are also almost entirely impermeable, which makes them a great choice when you need a construction to be airtight.

How Strong Is A Medium Dense Block?

Medium dense blocks such as the Hemelite 3.6N are an all-purpose concrete block that strike a balance between weight, strength, thermal and acoustic performance.

A medium dense block can come in either a 3.6N rating, or 7.3N. Either rating will perform well when it comes to fire resistance and sound blocking. A medium dense concrete block is made from a mix of sand, cement and lightweight aggregates, delivering strength, while minimising structural load on the foundations.

How Heavy is a Medium Dense Block?

A Holcim Star Performer weighs from 15kg for a 3.6N block and 20kg for a 7.3N block, so you will likely need to lift them with two hands apiece. However, it’s still less than a bag of cement that usually comes in 25kg bags.

The Holcim block is easy to handle as its open structure allows for gripping with one hand. Other solid blocks, such as the Hemelite range are still lighter than other, traditional concrete blocks, but without sacrificing performance or durability.

Best Practise:

In cold weather it is always a good idea to protect your masonry walls from frost, either with hessian cloth or polythene sheeting. If the mercury is seen to dip below 2˚C it’s not a good idea to lay blocks or bricks. Traditionally, 5˚C and rising is acceptable.

What are Solid Dense Concrete Blocks?

Solid dense concrete blocks are used wherever a serious loadbearing capacity is required. If the structural wall has to support multiple storeys, a gable end, or windloading, the denser the better.

Use Dense Concrete Blocks for:

- Situations where you require exceptional load bearing performance

- Below ground, top of strip footings to ground level

- Structural columns and retaining walls

- Areas where high compressive strength is required

Solid blocks are first choice for many below ground situations, or for retaining walls as they are extremely moisture resistant.

How Heavy are Dense Concrete Blocks?

A dense concrete block can weigh from 15kg up to more than 25kg, so care must be taken when handling them, or moving them around site. The heaviest blocks can be placed with a kerb lifter if required to save manual handling and ensure accurate positioning.

High strength materials that provide density are not all required to be heavy. A dense concrete block can often weigh the same as a lower density block.

What Are Dense Blocks Good For?

Holcim’s 140mm Dense Concrete Blocks are ideal for areas where there may be exposure to moisture below ground. Use them in your retaining wall or anywhere that a robust, durable foundation is required.

As a primary course to bring a wall up to level they are ideal, helping to deliver a solid base from which to build.

Best Practise:

It can sometimes be difficult to tell the difference between blocks, so always be sure to mark pallets clearly, or store different grades separately.

What are Coursing Blocks?

Concrete blocks come in a standard size, designed to fit most builder’s requirements, and they’re so successful that the dimensions have hardly changed over the years. A concrete block, by rule of thumb, is about equal to three brick courses in height.

It is not unusual to find that there may be one or two courses of brick, or a specific height requirement, that cannot be accommodated by the standard block size.

In this case, coursing blocks, that are smaller, will help regularise your wall.

Use Coursing Blocks to:

- Adjust course levels to maintain accuracy

- Infill around openings such as windows and doors to reduce the need for cutting blocks

- Make up levels in beam and block flooring

- Protect against cold bridging

Coursing blocks are made from the same material, and have the same properties as regular blocks, to maintain consistency across your wall.

What Are The Benefits of Coursing Blocks?

Coursing blocks reduce the need to cut blocks on site to achieve the right wall dimensions. This minimises waste, and helps to maintain a tidy site, and clean coursing mortar lines.

Use coursing blocks to save time too. Ultimately, coursing blocks should be part of the overall build plan, which will make your project more cost effective.

Help With UK Building Regulations.

The regs that outline what you need to do with regard to sound deadening and noise protection are found within Part E of the Building Regulations.

The regs that deal with insulation and thermal requirements for any new construction are found in Part L of the Building Regulations.

The Technical Stuff

For detailed technical data it can sometimes be useful to refer to a manufacturer’s website, which will often have free to download reference documents.

Get in Touch

The Gilmore team are specialists in block supplies and can help you with specifications, delivery, and any other query you might have. Contact us by email today or call on 01902 366620 to discuss your requirements.